- Sub-micron placement accuracy

- Superior optical resolution

- Excellent price performance ratio

- Manual or semi-automatic machine versions

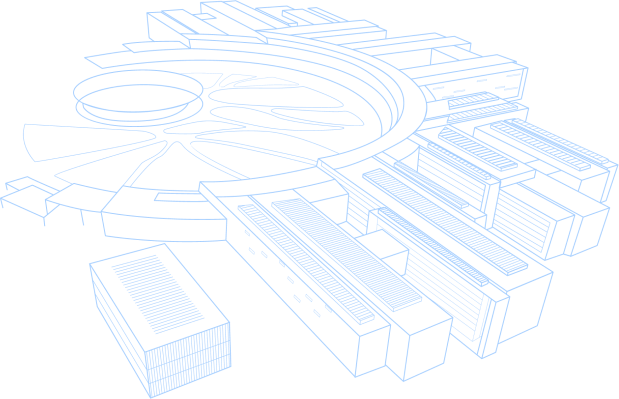

- Individual configurations with process modules

- Numerous bonding technologies (adhesive, soldering, thermocompression, ultrasonic)

- Data/media logging and reporting function

- Wide range of controlled bonding forces

- Various bonding technologies in one recipe

- Process module compatibility across Finetech platforms

- Modular machine platform allows in-field retrofitting during entire service life

- Synchronized control of all process related parameters

- Overlay vision alignment system (VAS) with fixed beam splitter