MEMS Micromirrors, or Microelectromechanical systems (MEMSs) mirrors, have recently become an essential component in optical scanning technology due to their compact size and versatile capabilities, such as light steering, modulation, and switching. MEMS micromirrors are gradually replacing traditional bulky galvanometer scanners and are widely used in applications like medical imaging, display projectors, light detection and ranging (LiDAR) systems, and optical switches.

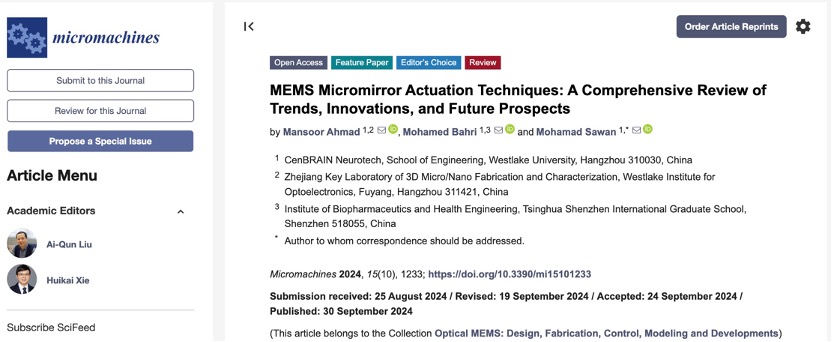

A recent review article from the CenBRAIN Neurotech, published in the Micromachines journal, delves into the various actuation technologies for MEMS micromirrors and elaborates on their fundamental working principles. This article provides valuable insights for researchers and engineers in selecting and applying appropriate micromirrors in optical scanning technologies.

Dr. Mansoor Ahmad, an engineer from CenBRAIN Neurotech is the first author of this work, Chair Professor Mohamad Sawan, is the corresponding author. The authors would like to express special thanks to Westlake University, the Westlake University Institute of Optoelectronics, and the Key Project of Westlake Institute for Optoelectronics (Grant No. 2023GD004).

Abstract

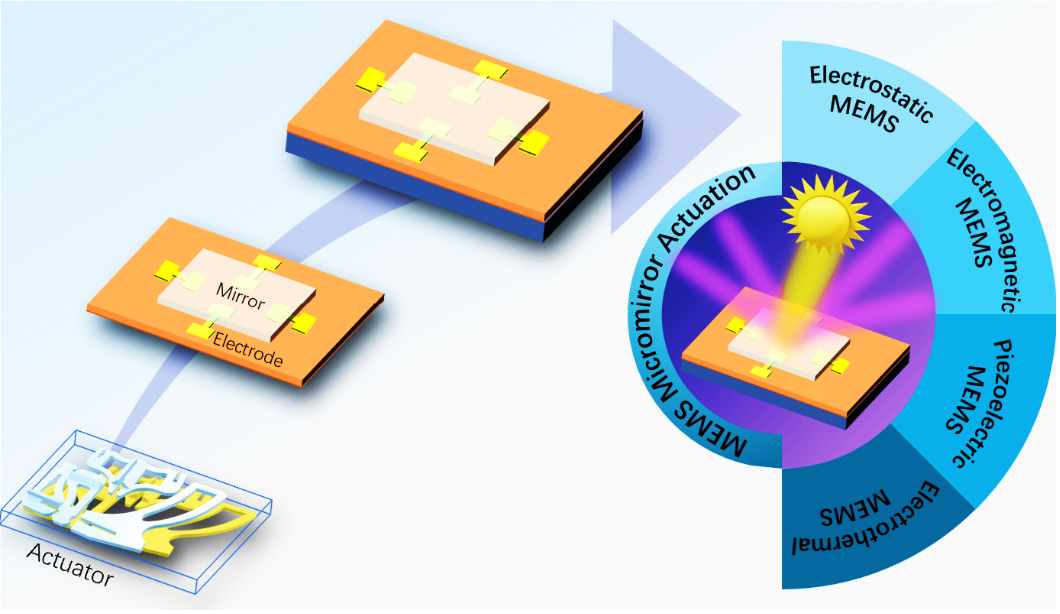

Fig.1. Graphical Abstract

The MEMS micromirror surface is coated with a high-reflectivity layer. When incident light strikes the reflective surface, it is reflected, and by actuating the mirror's movement, the light can be controlled. The performance of MEMS micromirrors primarily depends on the selection of the actuators, directly affecting response time, scanning angle, and power consumption.

This work reviews 208 closely related papers indexed in Web of Science, focusing on the ongoing innovations and research gaps in the four main actuation mechanisms for MEMS micromirrors. The article details their basic principles, advantages, and limitations:

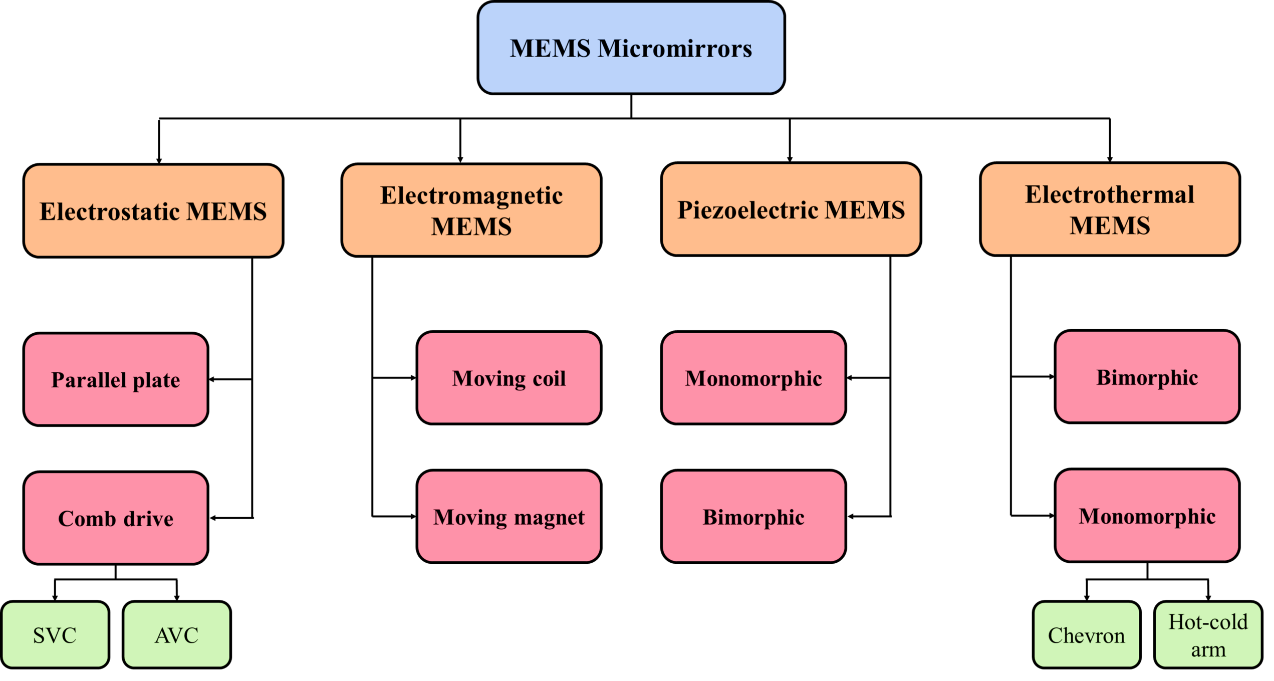

A) Electrostatic actuation: Fast and low power, but requires high voltage, suitable for small mirrors and high-speed scanning.

B) Electrothermal actuation: Low driving voltage, large deflection angles, and strong force, but suffers from heat dissipation and slower response time.

C) Electromagnetic actuation: Supports high-speed scanning and large deflection but requires bulky external magnets.

D) Piezoelectric actuation: Low power and moderate voltage, but complex manufacturing process and limited scanning range.

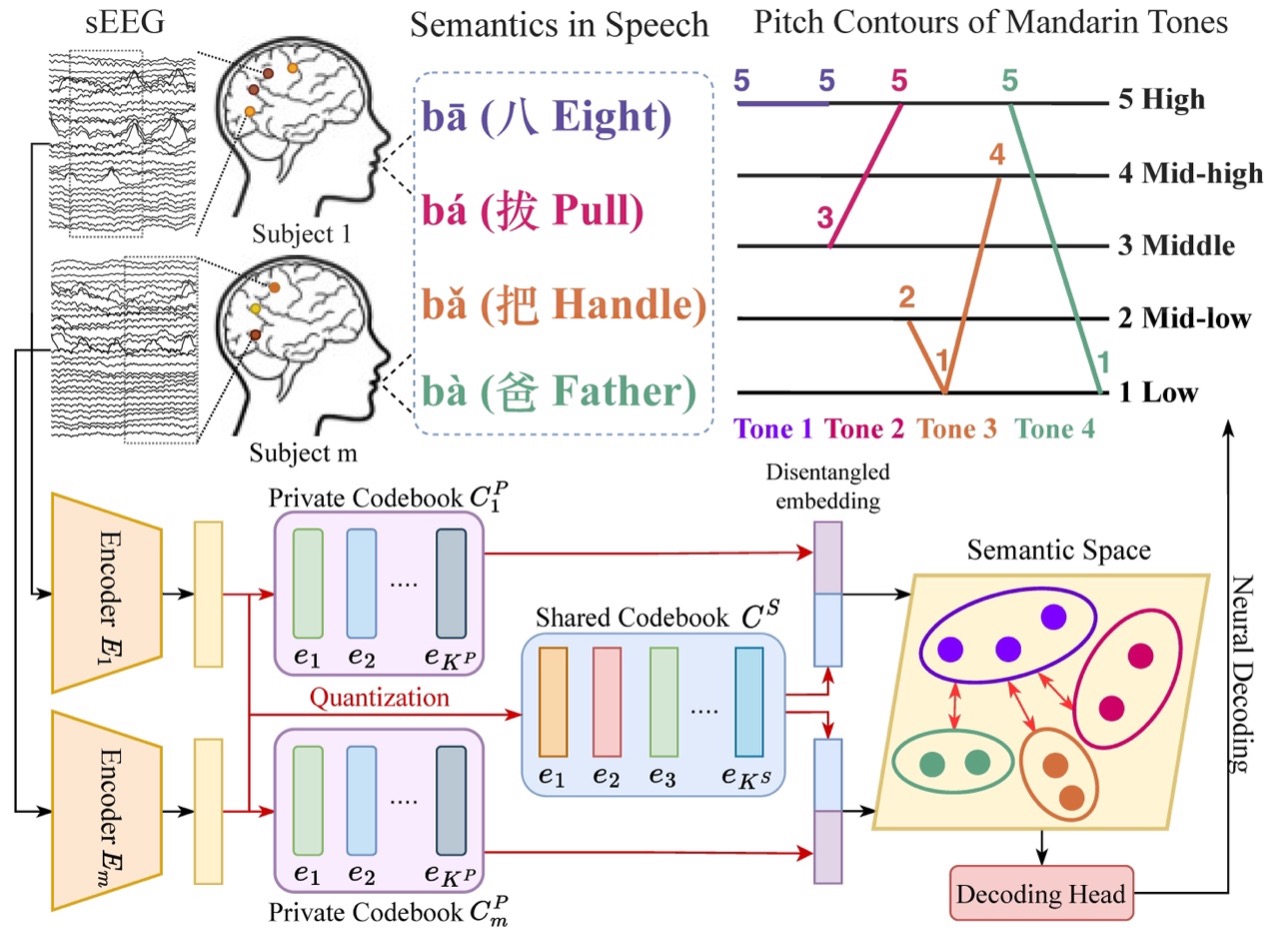

Fig.2. Block diagram of MEMSs micromirror actuation methods.

Additionally, hybrid actuation designs combine multiple technologies into a single device, enhancing control precision, scan range, and durability. With continued advancements, hybrid actuation and more efficient micro-mirror designs are expected to further expand their applications across various fields.

Research Highlights

1. Analyzed the working principles and advantages/disadvantages of the four actuation mechanisms.

2. Explored the performance and potential of MEMS micromirrors in various applications.

3. Proposed hybrid designs that combine multiple actuation mechanisms, driving further technological advancement.

Reference

Ahmad M, Bahri M, Sawan M. MEMS Micromirror Actuation Techniques: A Comprehensive Review of Trends, Innovations, and Future Prospects. Micromachines. 2024; 15(10):1233. https://doi.org/10.3390/mi15101233

https://www.mdpi.com/2072-666X/15/10/1233#B21-micromachines-15-01233